The 3-Way Classic Part 2.

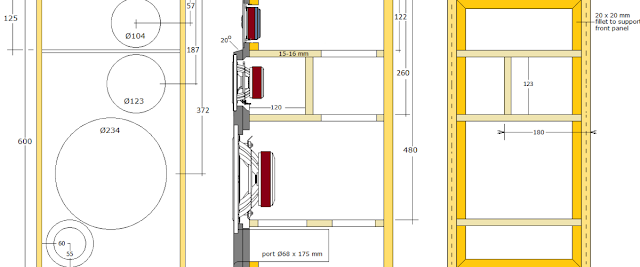

Troels Gravesens site contains cabinet drawings and build instructions for the SBA 3WC. WAF dictated white speakers so I decided to make the outer shell in MDF and the inner bracing in plywood. MDF pieces for the 3WC and two 30x30x30 sub-woofers in the picture below.

Routing all the holes in the bracing was quite tedious and I used the bench saw to make rabbets.

Outer MDF pieces and bracing glued together. Rabbets making it super simple to position and keep bracing in place.

Next up was the sub woofers. I recessed the top of the enclosure 1 cm and used the table saw to make a rabbet around the top part and a grove for the rabbet on the side panels.

And this is how the top and sides comes together.

Making a seamless joint between the top and side pieces.

The top of the sub-woofer with the top part recessed 1 cm.

The bottom of the down firing sub-woofer.

I wanted SpeakON connectors on the speakers but I did not want them to extend backwards, I wanted them on the bottom but there they would extend too much if I wanted to use a shallow plinth. The solution was to recess the connectors using a piece of plywood as an adapter from the inside of the 19 mm MDF.

The diameter of the hole in the bottom equals the outer diameter of the SpeakON connector. The hole was chamfered and the plywood adapter glued from the inside.

And this is what it it looks like with a 90 degree SpeakON connector attached.

The plinth for the 3WC and legs for the down firing sub-woofers where made out of 19 mm black Valchromat. The plinth fitted in the recess on top of the sub-woofer.

Pieces that will make up the legs for the down firing sub-woofers.

The vision is finally coming together. This is what the sub-woofer and 3WC looks like separately. The 3WC is still missing a baffle and the photo is therefor from the side of the 3WC.

And this is what they look like on top of each other. The plinth fits perfectly in the recess on top of the sub-woofer. The total height is 1 meter.

This marks the end of the second part about my 3-Way Classics. The next step is to make baffles for the 3WC. But it will take a while since I have to put this project on a back burner because of another project. More about that in another post...