Technics SL-23 restore and revamp, Part 3.

Next up is the revamp part. I wanted to try what is called engineered or reconstituted wood veneer. It is made from rotary peeled timber that is color enhanced, reformed to a square log and then re-sliced into rectangular veneer sheets. You may think of it as fake veneer out of reconstituted wood. The one I bought was paper thin (0.2 mm) and paper-backed but I first need something to cover it with, right?

Most of this build was made with leftover material from my scrap bin. I started out with a piece of 8mm MDF cut a bit oversized (it will later be trimmed to size on the router board). I marked out holes and made a first cutout with an electrical jigsaw.

I then used the original plint as a template and trimmed it flush on the router board.

I now got a simple baffle to start build upon:

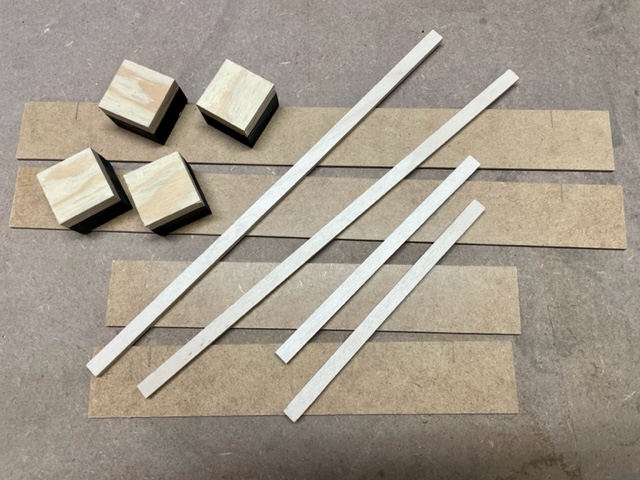

The original plint has a bevelled front but I wanted the plint visually separated into two pieces. One uniform plinth and a lower section holding the feet. I started out with an outer frame around the edge of the baffle and an inner section equal to the original bottom piece. I also glued and cut pieces that will make up support for and a frame around the rubber feet.

And this is how it all is supposed to come together:

I will reuse the bottom piece and this is how it will fit on top of the frame around the feet:

The original plint got 3mm bolts inserted from the top sticking out of the bottom of the plint. It felt a bit over complicated so I went with a layer of plywood as the next layer and I will use wooden screws from the bottom instead of the 3mm protruding bolts.

I finally got something that I could cover with the paper-thin veneer. I used spray glue on the plint and on the paperback of the veneer. I then just wrapped it around the MDF and trimmed with a packing knife. This is the untreated wood veneer. It looks like wood and it feels like wood and it is really thin. It starts to look like a real plinth...