The ESP based DIY preamp Part 3.

First a couple of words about safety. Regulations vary between countries, even though we got some common specifications within the EU. Anyone building any appliance supposes to know what they are doing and what your local safety regulations stipulate. I choose to build my preamp as a Class II device. It is normally not recommended but I do have my reasons.

I live in an old house without safety ground in the rooms where the preamp will be powered (according to old and now obsolete Swedish standard). I also got other Class II devices that will be connected to the preamp. I luckily got a copy of the IEC 60065 2001 specification and I have tried to follow it as close as possible. There are deviations, but nothing I worry about from a safety perspective. What I am trying to say is that you have to do your own due diligence from a safety perspective, if you ever decide to make your own electrical appliance.

I ordered most of the components from Mouser, a surprising amount are needed for this preamp.

I wanted high quality insulated and mains approved switches for the front-panel. I went with those from Marquardt and I bought enough for a matching power amp. I also got a couple of nice knobs from a vintage amplifier that I wanted to reuse.

I also needed something for my balance and volume control. I bought a couple of cheap 24-position rotary switches from China. You get what you pay for so I had to mod them before they were usable.

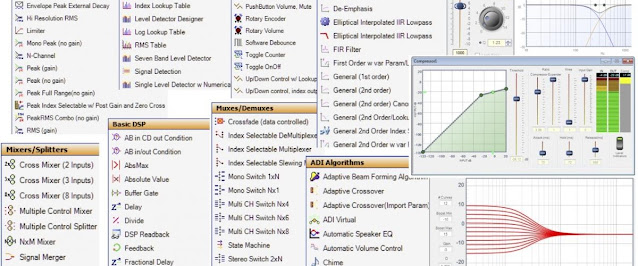

All of the ESP boards soldered.

And the rest of the boards etched, drilled and soldered.

Next up was an enclosure. I wanted something vintage looking, but with a modern twist. I was seeking inspiration from the cabinet of my Yamaha CA-600. It got an inner chassis that fits like a drawer in a wooden outer shell. I decided to make start out with an inner chassis made out of 4 mm birch plywood. I might replace it with a metal chassis in the future, but I like working in wood and it's easy to work with when prototyping. It also fitted with the idea of a Class II build.

This picture is from an early stage when I was trying to fit everything into the chassis. I was also trying different wiring schemes out testing each board out as I connected them. It was all rewired in the end with shielded wires for signal leads and twisted pair for power and switches. I ended up crimping 193 DuPont female sockets! One side of the wooden chassis is missing in the picture below. It was fitted in the end and is also the one the faceplate is fastened to.

I used some MDF scrap pieces to make the wooden outer shell. I used the McIntosh Stereotech as an inspiration for the ventilation takeouts. The inner wooden box rides on a wooden boarder elevating it 8 mm. It makes allowance for screw heads from the bottom and also serves as a ventilation channel. Air passes from the bottom through holes under the different boards and out of the top of the box.

I used some perforated aluminum sheet to make up some ventilation grilles.

I was initially planning to cover the wooden outer shell with some exotic veneer. But I changed my mind, prepped the surface and painted it in RAL 2004 orange! I thought it would go well with an aluminum faceplate and black trimmings.

I ordered the faceplate from Schaeffer AG (that would be Front Panel Express in the US) using their Front Panel Designer software. I have used their services before and they are just the best. I also used their UV-printing service for all the labels. It's cost efficient and looks like a screen print.

This marks the end of this third post about my ESP based DIY preamp. The next post will be about the final result.