The 3-Way Retro Part 4.

A quick build update and some initial measurements. Finalizing the boxes was quite straight forward. Inner walls fit like drawers into the grooves in the sides (note holes one one side and NO holes on the other where the mid goes). Make sure you get a solid bond with the baffle. I am using PVA glue for everything except for the back piece.

Two additional pieces forms the chamber for the mid (just like on the 3WC). Let the glue cure and then seal everything with some acrylic caulk.

Hard to see maybe but the connectors are not fully countersunk since there will be veneer put on top of the MDF. I also made the rabbets for the back piece 1 mm too deep. I will use an edge flush trim router bit to trim them flush with the back piece. Pretty important to get right before applying veneer to the back piece.

I used Casco SuperFix+ insted of PVA for the back piece. I did it to make sure I got an airtight bond since it would be really tricky to apply acrylic caulk through the holes in the baffle. Some of the excess can be seen in the picture below and compared with the acrylic caulk in the same picture to the right behind the XO.

I reused the passive crossovers from my 3WC build. Here fastened to the bottom of the box with Velcro.

The boxes are now done except for the veneer so I thought I would try mount the elements and take some initial measurements. I thought it would be interesting to compare the boxes with and without acoustic stuffing. So I stuffed one of the boxes quite heavily (more than I usually do), both the woofer and mid cavities. The other box was left empty.

It is already quite cold in Sweden so I decided to do the measurements indoors (therefor the psychoacoustic smoothing in REW). The setup was quick without using a turn table to measure every angle. I already know what to expect in directivity from my 3WC build.

First up a near field measurement of the woofers. Do not pay too much attention to dB values since I did not calibrate for SPL. I was a bit surprised by the difference stuffed vs non stuffed. Seems like f3 would be around 45 Hz stuffed and 50 Hz non stuffed. You give up some efficiency for a deeper and smoother response. I could see myself using this speaker with an all passive filter for music.

Next up is the far field measurement of the woofers.

Next up was to use the Merger tool in VituixCAD to merge the woofers near field response with its far field response (no correction for baffle step loss). I then applied a bog standard Linkwitz-Riley 2nd order filter @ 600 Hz. This is what it looks like for the merged measurements from the stuffed box (simulated in VituixCAD, smoothing 1/6 oct.).

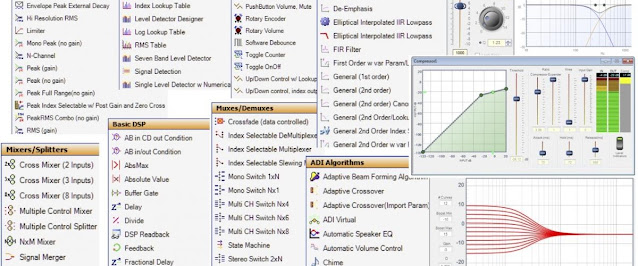

I see no major changes to the frequency response using a 4th or 8th order filter instead of the 2nd order. But the phase response from a 4th order seems better so I might try it instead of the 2nd order I used in my 3WC build. I now just have to wait for the veneer to show up from Germany and the DSP from China...